Innovated Water Soluble Packing

¡@

¡@

¡@

¡@

¡@

¡@

¡@

The water soluble film is based on the synthesis of polyvinyl alcohol (PVAL), a polymer developed in Germany during the 1920's. The first grade of PVAL cold water soluble film was introduced in 1961 to package consumer laundry detergents.

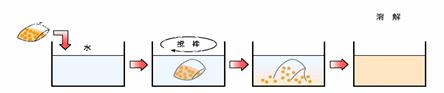

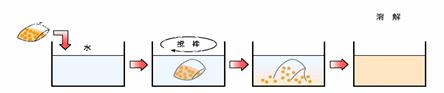

Since that time, the water soluble film has been commercially successful in a variety of industries. The film's ability to isolate its contents from the point of packaging to the point of film dissolution protects the environment/workers from exposure to the contents and keeps the secondary package contamination-free, eliminating container disposal problems. This "closed handling system" has come to be recognized as the preferred method of transporting, storing and handling toxic and other problematic liquids, powders and solids.

Pre-measured material packaging avoid troublesome measurement on the field

The water soluble film is impervious to odors, bacteria, carbon dioxide, hydrogen and oxygen. The film is readily permeated by moisture and ammonia.

The water soluble film prevents a number of organic solvents and natural oils from migrating through the film.

A large variety of microorganisms (existing freely in most environments) have been proven to degrade PVAL.

While the film is not approved for food packaging applications, independent studies on fish have shown the water soluble film to be non-toxic. Additionally, PVAL is a common component in cosmetics.

The water soluble film is exempt from tolerance under 40 CFR 180.1001 (d) and is approved for use as inert ingredients in pesticide formulations applied to growing crops.